FOOD LINE

Our Food Line timing belts meet FDA and EU/EC regulations and stand apart for their excellent surface quality.

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Our timing belts face huge challenges in the food industry’s hygiene-critical environments. We offer first-class, food-grade solutions for exacting hygiene standards.

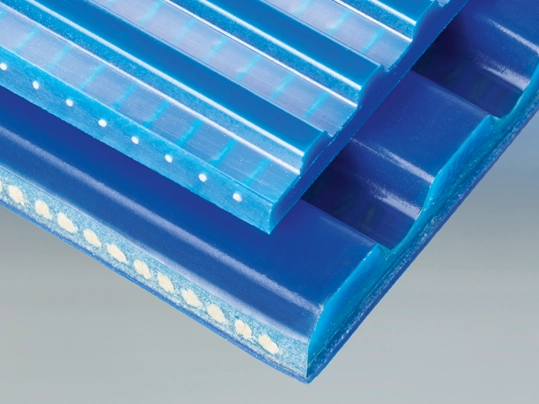

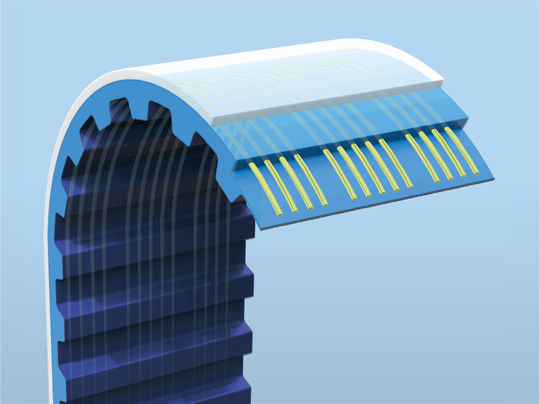

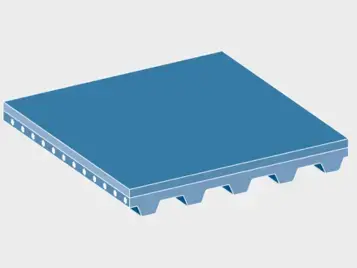

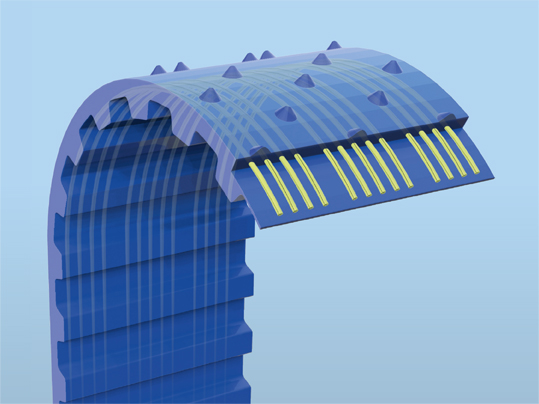

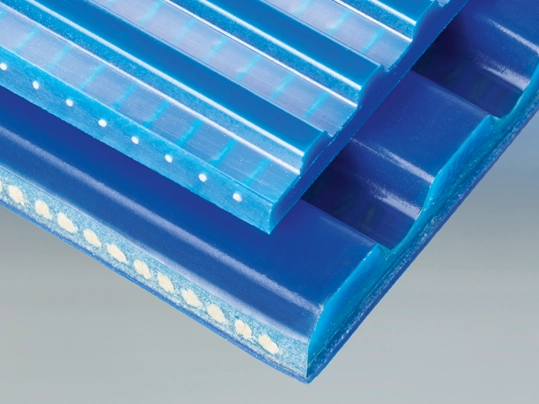

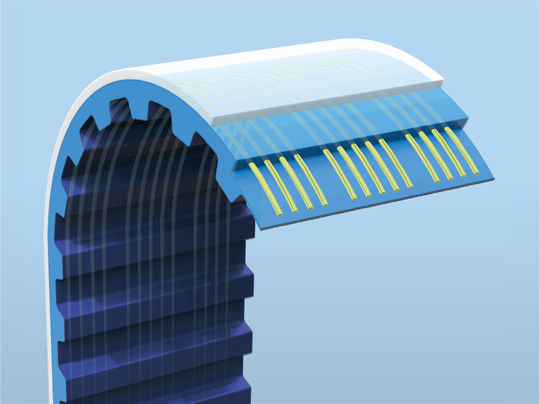

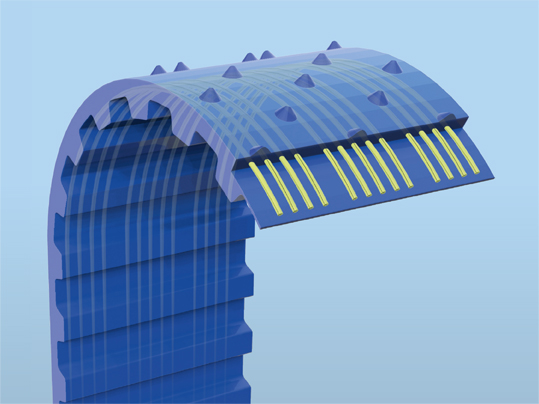

First-class food safety is what defines our Food Line timing belts. After all, these belts are custom designed for direct contact with food. We have timing belts for any application, making them versatile options anywhere. Diverse designs, profiles, coatings, and patterns on the back guarantee perfect solutions for your requirements. Fully enclosed tension members and a lack of coiling noses render contamination impossible and facilitate cleaning. As a result, unpackaged food, detergents and water can’t come into contact with exposed tension members. The result: Superior standards of hygiene.

”We realize that each production process is unique and requires the timing belts to match. The type of timing belt is crucial to flawless conveying throughout the production line. Which is why we provide tailored advice so that you receive the right timing belt for your process. We understand your requirements so can recommend the ideal timing belt for your production line and guarantee top performance.”

Our coated timing belts are a benchmark for superior hygiene in food processing. Thanks to a variety of configuration options, we can offer you the ideal solution. Independent test labs confirm that these timing belts meet the stringent requirements of the FDA and EU. Feel free to contact us for a declaration of conformity.e-mail

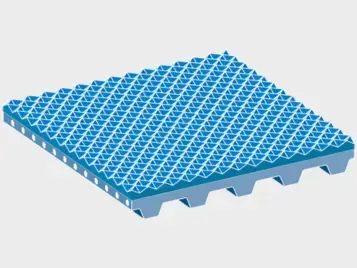

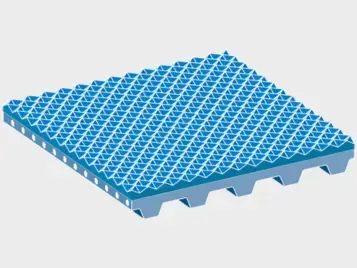

Our PU 85/NP coating is made of polyurethane with a Shore A hardness of 85 and has an inverted pyramid pattern. The coating stands apart for its superior chemical resistance, exceptional incision- and wear-resistance and has good release properties in terms of the products conveyed. The NP pattern makes the coating ideal for inclined and other types of conveying. This coating is used on feeder belts to packaging machinery and for conveying dough products, meat and sausages, as well as fish.

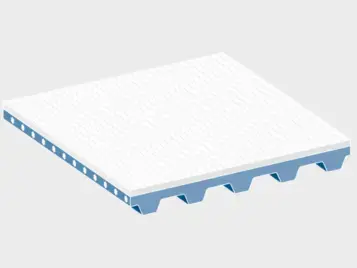

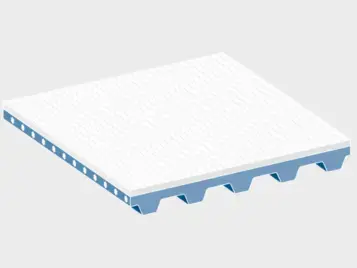

The PU 85/FSTR coating has a finely patterned top face. The polyurethane with its Shore A hardness of 85 offers outstanding chemical resistance, excellent incision- and wear-resistance and good release properties in terms of the products conveyed. This coating is used for feeder belts to packaging machinery and for conveying dough products, meat and sausages, poultry, fish, and confectionery.

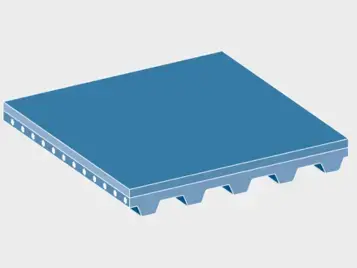

The R 60 has a high-grip, finely patterned surface. The coating is very abrasion resistant and particularly ideal when good grip and accurate positioning are required. This coating is used in packaging machinery, in the meat and fish industry, for dough products and confectionery.

To comply with stringent hygiene requirements, we make tooth profiles and patterns on the backs in one single process.

The result is a homogenous product without any hidden contamination.

The wide range of patterns on the backs enables multiple efficient processes in the food industry.

.webp)

The truncated cone pattern on the back consists of staggered rows of cones. The tips of the cones are blunt. This pattern is used on belts destined for bacon and ham processing.

.webp)

This pattern on the back consists of small, tapered nub tops. It’s ideal for belts conveying meat and slices of sausage.

.webp)

The Triangle pattern has grooves across the width. It’s used on belts conveying slices of cheese and other products.

.webp)

The LNP pattern consists of staggered lengthways rows of nub tops. This pattern is frequently used in various applications in the sausage industry.

.webp)

The LG pattern on the back consists of lengthways grooves. The pattern is ideal for products like feta cheese or lettuce that need draining during production.

.webp)

The GL pattern has a smooth surface and is used for general conveying tasks.

First-class food safety is what defines our Food Line timing belts. After all, these belts are custom designed for direct contact with food. We have timing belts for any application, making them versatile options anywhere. Diverse designs, profiles, coatings, and patterns on the back guarantee perfect solutions for your requirements. Fully enclosed tension members and a lack of coiling noses render contamination impossible and facilitate cleaning. As a result, unpackaged food, detergents and water can’t come into contact with exposed tension members. The result: Superior standards of hygiene.

”We realize that each production process is unique and requires the timing belts to match. The type of timing belt is crucial to flawless conveying throughout the production line. Which is why we provide tailored advice so that you receive the right timing belt for your process. We understand your requirements so can recommend the ideal timing belt for your production line and guarantee top performance.”

Our coated timing belts are a benchmark for superior hygiene in food processing. Thanks to a variety of configuration options, we can offer you the ideal solution. Independent test labs confirm that these timing belts meet the stringent requirements of the FDA and EU. Feel free to contact us for a declaration of conformity.e-mail

Our PU 85/NP coating is made of polyurethane with a Shore A hardness of 85 and has an inverted pyramid pattern. The coating stands apart for its superior chemical resistance, exceptional incision- and wear-resistance and has good release properties in terms of the products conveyed. The NP pattern makes the coating ideal for inclined and other types of conveying. This coating is used on feeder belts to packaging machinery and for conveying dough products, meat and sausages, as well as fish.

The PU 85/FSTR coating has a finely patterned top face. The polyurethane with its Shore A hardness of 85 offers outstanding chemical resistance, excellent incision- and wear-resistance and good release properties in terms of the products conveyed. This coating is used for feeder belts to packaging machinery and for conveying dough products, meat and sausages, poultry, fish, and confectionery.

The R 60 has a high-grip, finely patterned surface. The coating is very abrasion resistant and particularly ideal when good grip and accurate positioning are required. This coating is used in packaging machinery, in the meat and fish industry, for dough products and confectionery.

To comply with stringent hygiene requirements, we make tooth profiles and patterns on the backs in one single process.

The result is a homogenous product without any hidden contamination.

The wide range of patterns on the backs enables multiple efficient processes in the food industry.

.webp)

The truncated cone pattern on the back consists of staggered rows of cones. The tips of the cones are blunt. This pattern is used on belts destined for bacon and ham processing.

.webp)

This pattern on the back consists of small, tapered nub tops. It’s ideal for belts conveying meat and slices of sausage.

.webp)

The Triangle pattern has grooves across the width. It’s used on belts conveying slices of cheese and other products.

.webp)

The LNP pattern consists of staggered lengthways rows of nub tops. This pattern is frequently used in various applications in the sausage industry.

.webp)

The LG pattern on the back consists of lengthways grooves. The pattern is ideal for products like feta cheese or lettuce that need draining during production.

.webp)

The GL pattern has a smooth surface and is used for general conveying tasks.