Meat processing

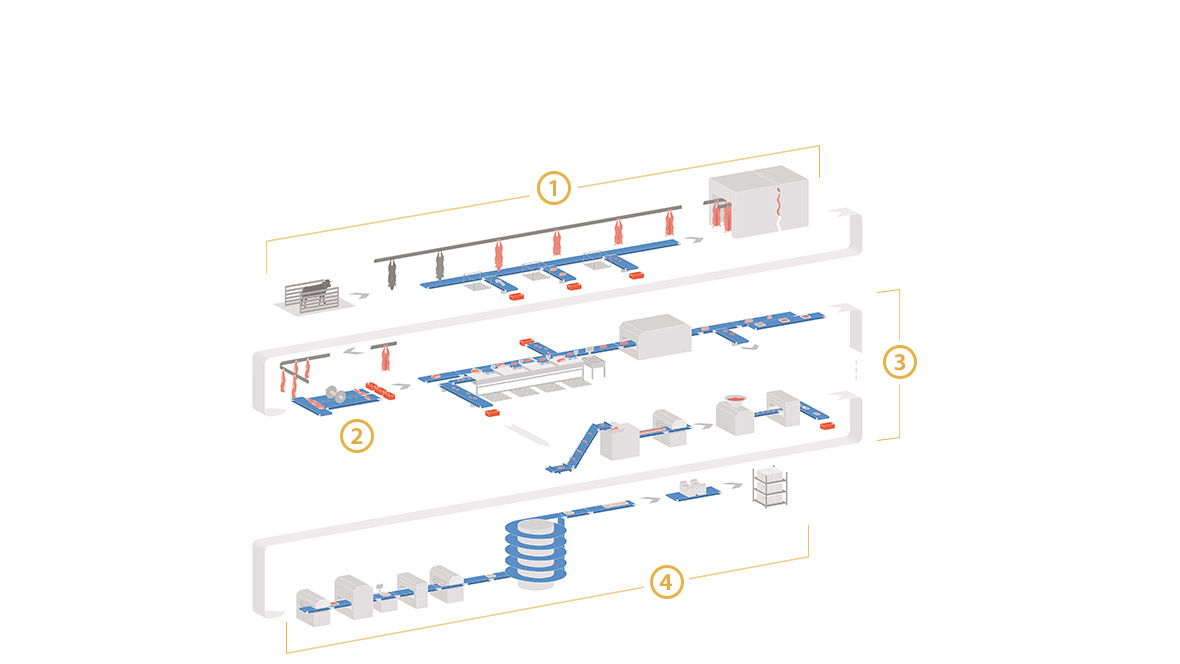

Meat processing is complex and multifaceted. It requires maximum precision, care, and compliance with hygiene standards. Conveyor belts play a pivotal role in conveying meat products after slaughtering the livestock to the final packaging stage.

The belts are at the heart of modern meat processing and ensure each production process runs smoothly. But not every belt is suitable for each step in the process.

To prevent contamination of meat and ensure top product quality, conveyor belts must meet different requirements in terms of material, shape, and cleaning options.

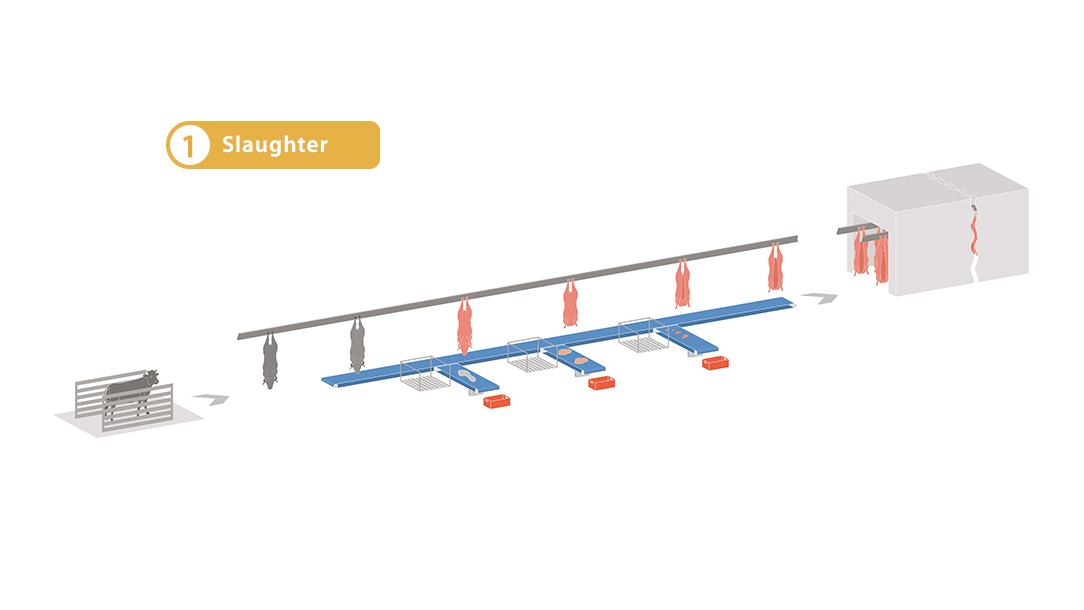

Once the livestock arrives, it’s stunned and slaughtered. The carcasses are hung up and the fur or bristles, rumen, intestines and other offal removed. Before processing any further, the carcasses are cooled in a separate chiller.

Technical Requirements of the Belts

The carcasses are usually transported hanging on chain or overhead conveyors. However, it’s belts that usually convey rumen and intestines. These conveyor belts need to withstand wear and tear and be easy to clean.

Compliance with top hygiene standards is crucial when offal is conveyed to the next processing stage.

Our solution

For conveying rumen, our plastic modular belts series 6.1 made of polypropylene (PP) are an excellent choice. Because you can clean them with hot water and their hinge pins are made of polybutylene terephthalate (PBT), they boast very long service lives.

HACCP belts with top hygiene standards combined with EU and FDA compliance are suitable for conveying offal to the next stage.

We offer coatings and belts for each conveying task at this step of the process.

Contact us if you’d like to know more

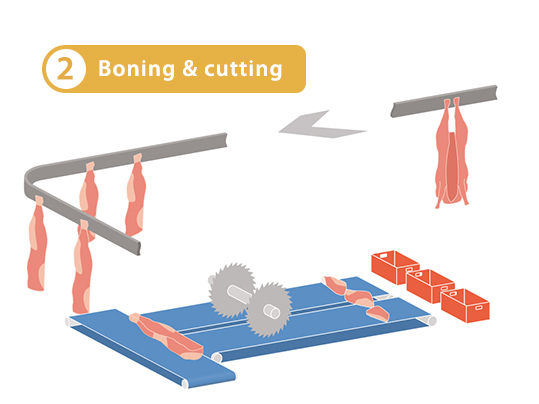

This step involves taking the meat off the bones and jointing it depending on the final product specifications. Afterward, the meat is usually conveyed through the factory in standardized boxes or trays. The slaughterhouse waste is taken out of the production process and disposed of via special waste conveyors.

Technical Requirements of the Belts

Boning and jointing meat requires a belt surface that’s both incision resistant and very hygienic.

Onward conveying of slaughterhouse waste places much lower demands on the belts’ mechanical load than conveying meat in boxes (crates/trays) for more processing. In this case, exceptional tensile strength is a must because the belts often have to run over steep inclines.

Regardless of their function, to meet demanding hygiene requirements, all belts must be easy to clean.

Our solution

For jointing, we recommend our Prolink plastic modular belts from series 6.1 made of cut-resistant and impact-resistant polyoxymethylene (POM-CR; CR = cut resistant). The belts’ exceptional impact resistance is reflected in their low cutting depth and low wear.

Our fabric-based Transilon belts with hard, cut-resistant polyurethane coatings are an ideal, robust option for jointing carcasses. To provide maximum protection from contamination, we can also add belt edge sealing (Smartseal) to many of these belts.

Our Prolink plastic modular belts from the 6.1 series made of polypropylene (PP) are reliable options for inclined conveying of boxes and trays. We also add an extra Friction Top surface to the belts.

Various easy-to-clean belt types are used to convey the slaughterhouse waste away.

Contact us if you’d like to know more

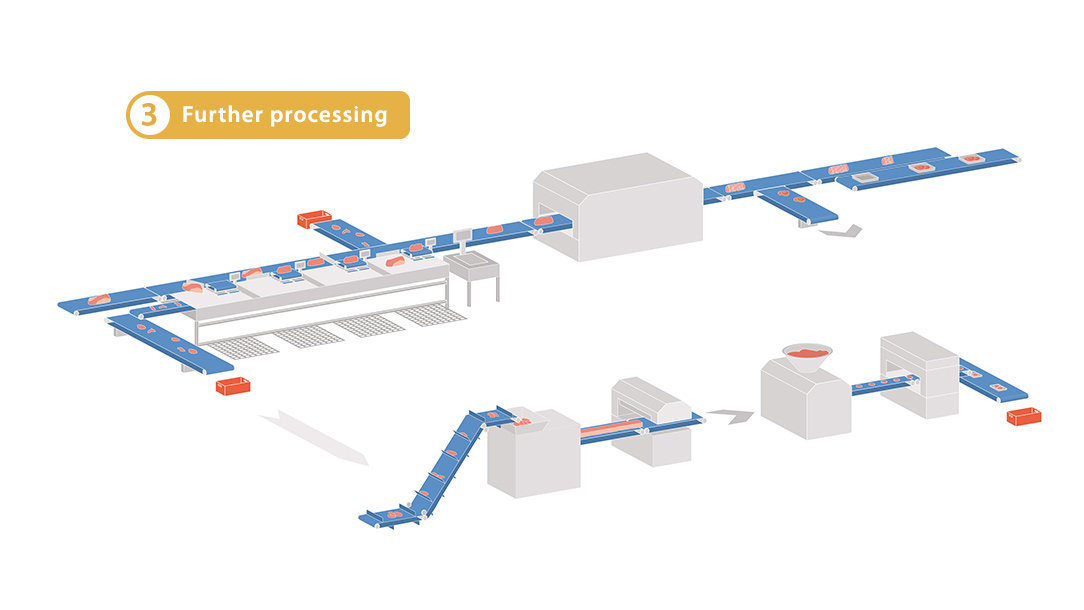

Do you want your final product portioned or seasoned? Depending on how you want to process your meat and ultimately ship it, lots of processing methods are possible or necessary. The way you derind, portion, form or season meat differs in lots of respects. And a range of conveyor and processing belts are on hand to help.

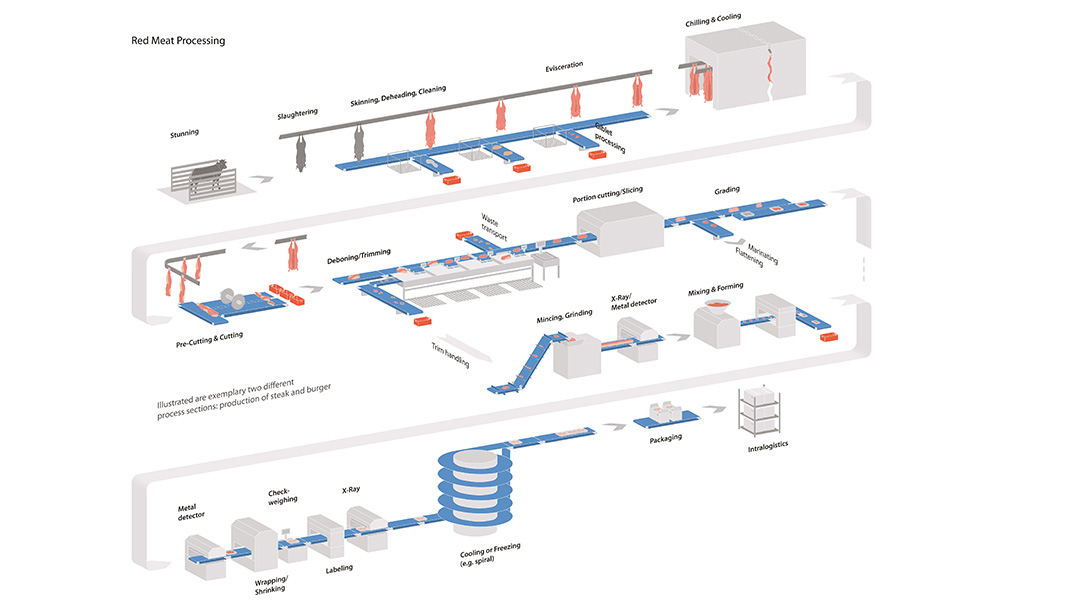

To give you an example, you can see the steps required to produce steaks and burgers.

Technical Requirements of the Belts

Alongside the general hygiene requirements, the parameters specific to the conveyor and process govern the technical requirements. For instance, a robust belt design, exceptional cut resistance, good grip, outstanding positioning accuracy, superior abrasion and chemical resistance or large open areas may be required. Every belt must comply with the relevant food standards.

Our solution

We offer homogenous belts, fabric-based types, and plastic modular belts for each sub-process. This portfolio means each step in the process is perfect. And you’ll be able to exploit your quality and productivity potential to the full.

Our HACCP-compliant belts allow direct contact with food, even where the most stringent standards of hygiene apply.

Transilon belts with a high k1% value and Prolink plastic modular belts from the 6.1 series are the first choice as tenderizer belts.

Precise positioning, for example during slicing or portioning, is achieved by belts with appropriate surface patterns and perforated strips at the edge.

For seasoning and marinating processes, we recommend our series 6.1 plastic modular belts with an open area of 23%.

Contact us if you’d like to know more

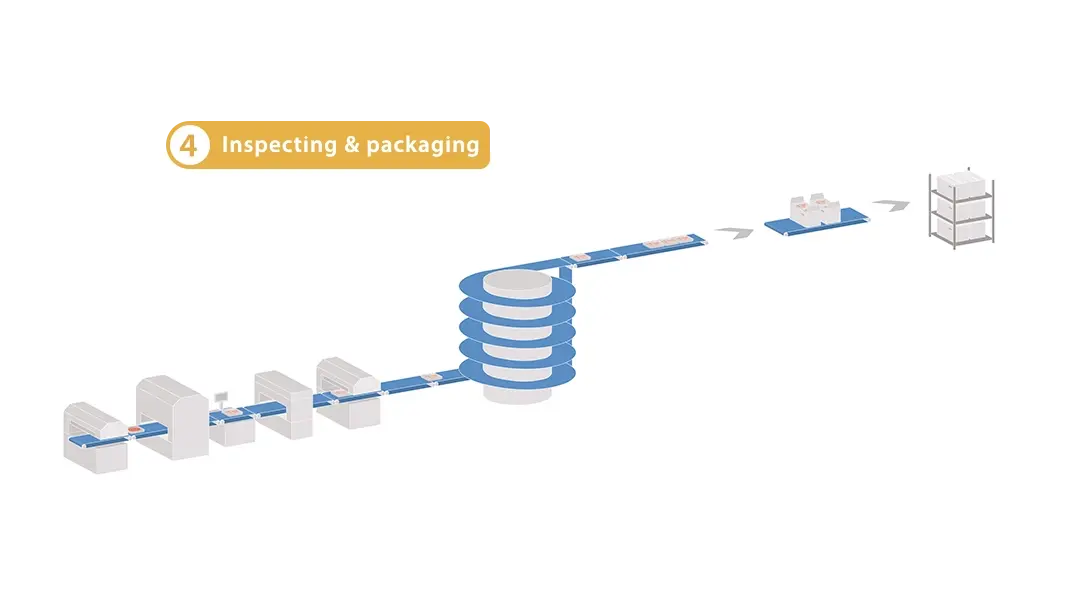

Detection methods help to inspect your products for foreign bodies. These can be integrated at different stages of the production process. Once your products are free of contamination, they’re weighed and packaged in units for sale. The main options are bags or trays, which are shrink-wrapped, labeled and, if necessary, repackaged and deep-frozen. However, the order this final step takes always depends on the system and product.

Technical Requirements of the Belts

Apart from being food grade belts with excellent cleaning properties, specific characteristics are required for each process step. For example, a constant belt thickness is essential during weighing. Good grip is crucial for exact product positioning, while good release properties are vital for labeling.

When metal detectors and X-ray machines are in operation, the requirements of the conveyor belts depend on the type of equipment. In the freezer section, it’s also important that the belting material doesn’t become brittle even at temperatures as low as -40°C.

Our solution

To guarantee reliability and consistent compliance with your HACCP concept, we have multiple special belt types geared to the various processes.

Special surface characteristics make the portioning and wrapping process easier and more reliable.

Special finishes for check-weigher belts provide extremely precise splices of the same thickness.

To suit your requirements, our range includes non-antistatic belts for metal detectors.

To ensure X-rays are good quality, we recommend belts with a high friction coefficient on the top face. As a result, your products can pass through the equipment’s safety curtain reliably.

Our food-grade Prolink series, made of polyoxymethylene (POM) or polyethylene (PE), have exceptional service lives when products need deep freezing. To withstand exceptional tensile forces in cooling towers, we fit stainless steel hinge pins to our curve-compatible Prolink belts.

Contact us if you’d like to know more

Raw meat, cooked meat, or packaged meat products all require specific processing. To show meat processing in as much detail as possible, we’re providing a behind-the-scenes look at steak and burger production processes.

Some steps in the process can differ from yours, just like the requirements you place on your belts. However, to guarantee consistent food safety, compliance with hygiene regulations is a must.

We’d be happy to talk about your production process and conveyor belt requirements.

Meat must be produced to a high quality and meet stringent food standards. Precision, hygiene, and efficiency play a key role in the whole process. Each step, from slaughtering the livestock to jointing the meat and packaging, requires specially adapted processes and equipment.

Conveyor belts play a key role in this sophisticated production process. Which is why we’re offering a wide range of high-quality belts geared to your meat processing requirements. Our product lines include special belt types that are tailored to each processing task and meet superior hygiene standards too. You can then easily put HACCP concepts into practice and help make food safe.

For flexible and seamless production, you can splice all our meat processing belts on the machinery itself. For Prolink plastic modular belts, this process is very straightforward and requires no special tools. There are also various splicing methods and appropriate equipment for fabric-based and homogenous belts.

Interested in finding out more about our top product quality, variety of belts and solutions geared to meat processing?

We’d be happy to advise.

Any questions about our meat processing products? Then contact us.

To the contact form