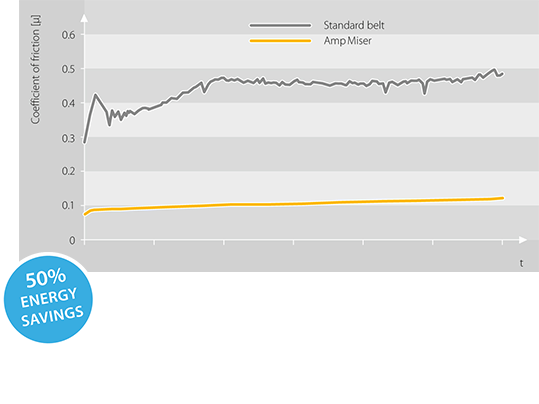

50% energy savings

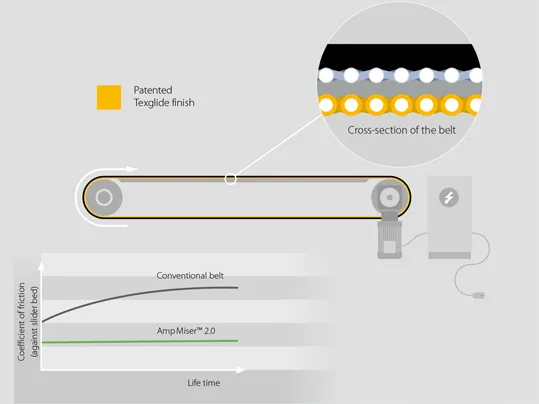

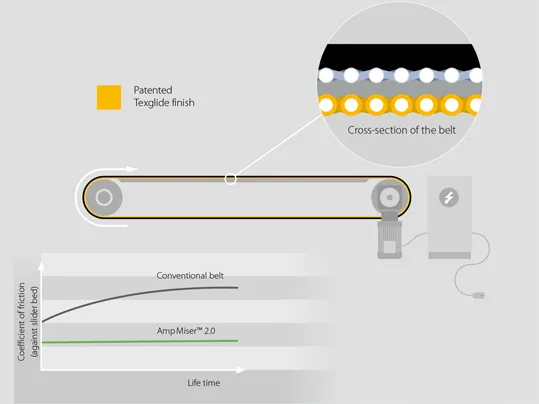

Amp Miser belts are equipped with patented Texglide at the underside fabric. A smooth layer is created that permanently acts like a dry lubricant and therefore minimizes energy consumption.

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

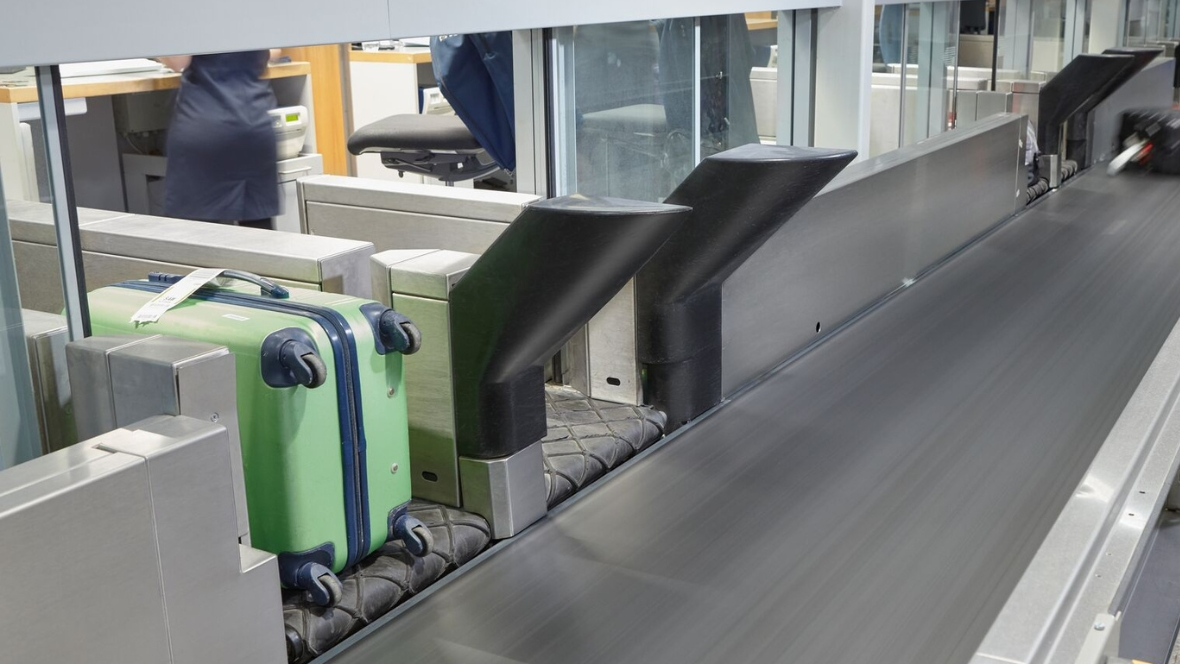

Amp Miser is the conveyor belt series from Forbo Movement Systems with which you can demonstrably save up to 50% energy. Reduce your energy consumption and CO2 emissions with Amp Miser. Certified by TÜV Rheinland.

One of Forbo’s key corporate objectives is to maximize environmental friendliness and to enhance product value at the same time. On this basis, we successfully conduct research and development by closely liaising with OEMs and end users. The energy-saving conveyor belts are another prime example of our approach.

TÜV Rheinland confirms that Amp Miser conveyor belts can realise significant energy and CO2 savings compared to conventional standard conveyor belts. For its savings potential of up to 50% of the energy required for power transmission, Amp Miser belts received the Best of Industry Award for Best Sustainability Project in 2023.

An additional sustainability benefit is derived from the selection of Amp Miser belts with tension member fabric made from 100% recycled PET bottles (Transilon ECOFIBER). Valuable raw materials are saved during production without compromising on quality and service life. At the same time, energy consumption and therefore CO2 emissions during production are significantly lower.

Amp Miser benefits

.webp)

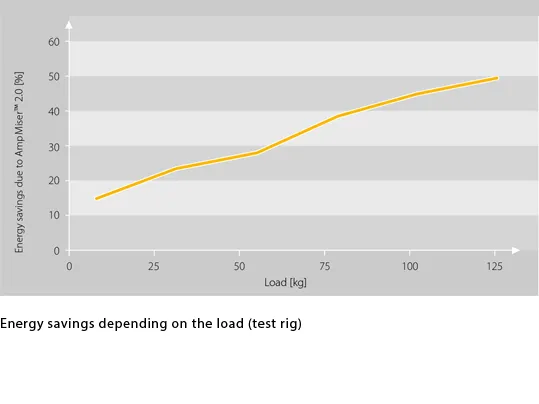

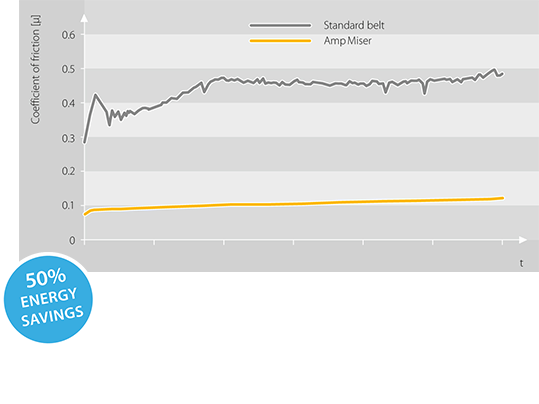

Tests confirm that our Amp Miser conveyor belts have 50% less friction than comparable energy-saving belts. The comparable belts have the same high friction as our to standard belts without Amp Miser technology.

This results in up to 50% energy savings for baggage handling and intralogistics conveyor systems as well as reduced CO₂ emissions to support sustainability goals.

Read more about the exact measurement in the white paper

%20(1).webp)

Use our Amp Miser calculator to find out your potential savings compared to a standard belt.

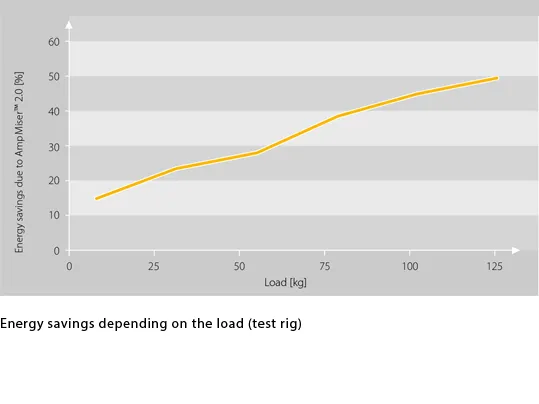

Maximum savings can be expected with long conveyors, high loads, high, constant speeds and in horizontal transport. However, the lower coefficient of friction of Amp Miser belts also reduces energy consumption under other conditions.

TÜV Rheinland has certified the Amp Miser calculator. Use the user-friendly online calculator now.

To the Amp Miser calculator

Forbo Movement Systems is equipping Schiphol Airport with conveyor belts. Together with the supplier of the baggage handling systems, we are working on reducing the energy consumption of the baggage handling system by using energy-efficient belts. The Winning Solution describes the project of introducing Amp Miser and measuring the savings potential.

To the Winning Solution

In the white paper "Saving energy operating baggage handling systems", we examine the results of measurements in the laboratory and on active airport systems. They prove the energy-saving potential, also compared to comparable energy-saving belts in the market.

Amortization calculations show that possible additional costs are more than compensated for. Secondary effects such as longer belt service life and longer conveying distances with an identical drive can further reduce the overall costs of the system.

To the whitepaper

Our Amp Miser experts will be happy to answer any questions you may have about energy-saving belts.

get in touch now

.webp)

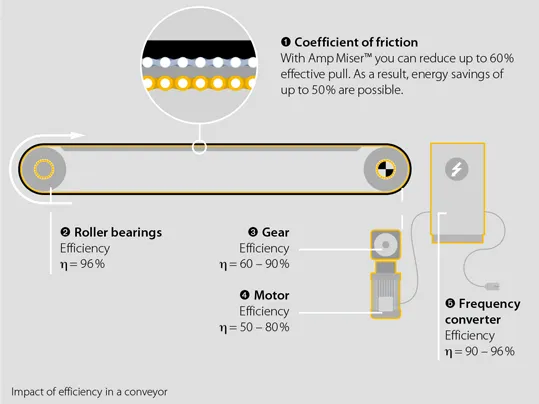

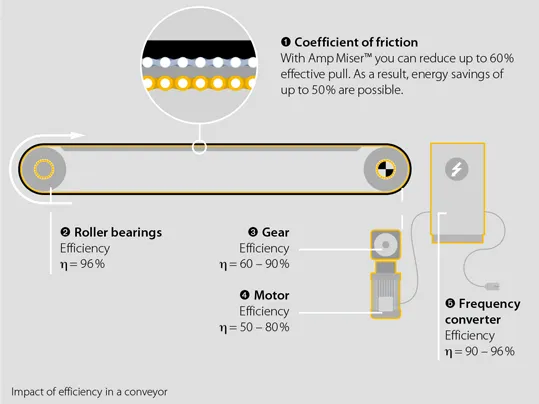

Due to a significantly reduced coefficient of friction, Amp Miser belts make an impact where energy losses in a conveyor are usually the greatest: in the friction between the bottom of the belt and slider bed. By adding patented Texglide to the underside fabric, a smooth layer is created that permanently acts like a dry lubricant and therefore minimizes energy consumption.

Amp Miser conveyor belts excel in areas where items are constantly conveyed and where many belts are in use, for example at airports and in logistics or distribution centers. Total energy savings of up to 50% have been measured In these types of applications.

Except where unpackaged food is concerned, the Amp Miser series is ideal for virtually any unit goods applications.

Further advantages are the resistance to chemical influences like kerosene vapors and the reduction of CO₂ emissions due to lower energy consumption.

| The properties | The advantages |

| ideal coefficient of friction for steel and zinc slider beds | energy efficient, eco-friendly, lower operating costs |

| lower coefficient of friction on the underside | less power required, longer conveyors possible with one drive |

| underside protected | cleanliness, long service life |

Our energy-saving Amp Miser belts have an excellent track record under the tough conditions in logistics centers and on baggage conveyors*. The Amp Miser belts with enhanced tension members and Texglide technology produce lower coefficients of friction between the underside of the belt and slider bed – even when slider beds are galvanized. No other changes to the conveyor are required.

*For more than 5 years Amp Miser conveyor belts have had a good track record in the following companies:

Compared with standard types, in typical applications with long conveyors and heavy loads, up to 50% energy savings are possible, now.

The second generation of Amp Miser types are also perfect on otherwise tricky galvanized slider beds. Compared with the previous belts, the coefficient of friction of this generation has been halved to

μ < 0.17. And it’s just μ < 0.13 on nongalvanized steel.

The quality, design and condition of all other mechanical and electrical components also play a major role in energy consumption as a whole. Small drives for example are usually not very efficient because a lot of the energy is required to drive the conveyor’s moveable parts alone.

Even with a low coefficient of friction, by using Amp Miser conveyor belts you can save up to 50% of the conveyor’s energy costs.

Significant savings can be made where:

The savings potential of Amp Miser, the absolute reduction in carbon emissions, as well as the online calculator’s accuracy, were independently confirmed by TÜV Rheinland.

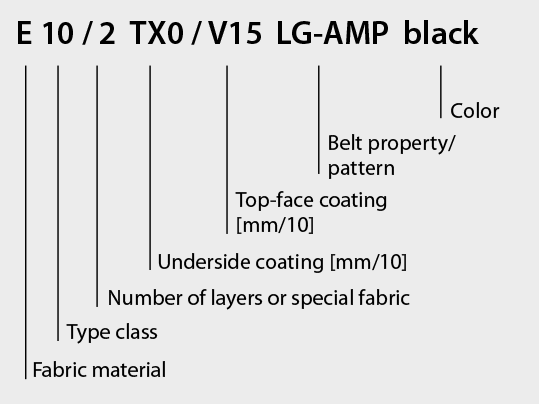

Article number | Total thickness approx. [mm] | Weight approx. [kg/m2] | Effective pull at 1% elongation (k1% relaxed) [N/mm width]1 | dmin approx. [mm]2 | Permissible operating temperature [°C] | Horizontal conveying | Inclined conveying | Accumulation conveying | Flame retardant SE according to EN340 | Flame retardant FR according to ASTM D-378 | Energy savings certified by TÜV Rheinland | |

| E 10/2 TX0/V5H MT-AMP black | 906807 | 1.9 | 2.1 | 9.0 | 40 | –10/+50 | ● | ● | ||||

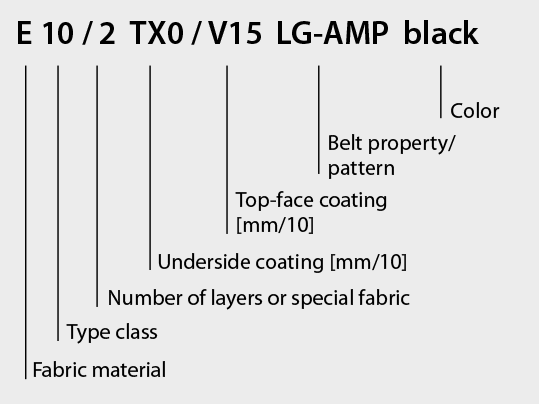

| E 10/2 TX0/V15 LG-AMP black | 906808 | 2.7 | 2.9 | 9.0 | 40 | –10/+50 | ● | ● | ||||

| E 10/2 TX0/V5H MT-SE-AMP black | 906809 | 2.2 | 2.5 | 9.0 | 40 | –10/+50 | ● | ● | ● | |||

| E 10/2 TX0/V15 LG-SE-AMP black | 906810 | 2.7 | 2.9 | 9.0 | 40 | –10/+50 | ● | ● | ● | |||

| E 12/3 TX0/TX0 FR-AMP gray | 907206 | 3.8 | 4.6 | 9.0 | 60 | –10/+50 | ● | ● | ● | |||

| E 12/2 TX0/V2 MT-M-FR-AMP black | 907224 | 3.0 | 3.6 | 6.0 | 60 | –10/+70 | ● | ● | ||||

| E 12/2 TX0/V1 | 907230 | 2.95 | 3.3 | 6.0 | 60 | –10/+70 | ● | ● | ||||

| E 12/2 TX0/V10 LG-M-FR-AMP black | 907229 | 3.9 | 4.5 | 6.0 | 60 | –10/+70 | ● | ● | ||||

| RE 10/2 TX0/V5H | 901015 | 2.2 | 2.6 | 8.5 | 36 | –10/+50 | ● | ● | ● | |||

| RE 10/2 TX0/V15 LG-SE-AMP black | 901016 | 2.7 | 2.9 | 8.5 | 36 | –10/+50 | ● | ● | ● |

Z-splice

Fulfils top demands on equal thickness. Very flexible splice. Standard splice for double-layer belt types.

Mechanical fasteners

For quick fitting and removal of the belt without dismantling parts of the conveyor.

AMP = AmpMiser

E = Polyester

FR = Flame retardant, ASTM D-378

LG = Longitudinal groove

MT = Matte

RE = Recycled polyester

SE = Flame retardant, EN340

TX = Texglide

V = Polyvinyl chloride

V…H = Polyvinyl chloride hard

1Established in line with ISO 21181:2005

2 Minimum drum diameter was determined at room temperature and does not apply to conveyor belts with mechanical fasteners. Lower temperatures require larger drum diameters.

What does Amp Miser mean?

Amp Miser is an abbreviation of “Ampere Miser”. The name emphasizes that installing an Amp Miser belt saves energy and improves your eco footprint as a whole. Our Amp Miser products are patented in Europe and the US. Patents have been submitted in many other countries too.

What does Texglide (TXGD) mean?

Texglide (TXGD) is a compound embedded in the underside of the fabric. Texglide isn’t just an add-on, or a coating, but a permanent feature of the bottom of the fabric throughout the belt‘s life cycle. Texglide guarantees low friction between the belt and the slider bed.

What material is recommended for slider beds?

Amp Miser belts can be used on slider beds of all types (such as wood, steel or galvanized steel). In the case of galvanized steel, the Amp Miser belts cut the coefficient of friction to under 0.17, as regards steel to 0.13 and to less than 0.06 in plywood.

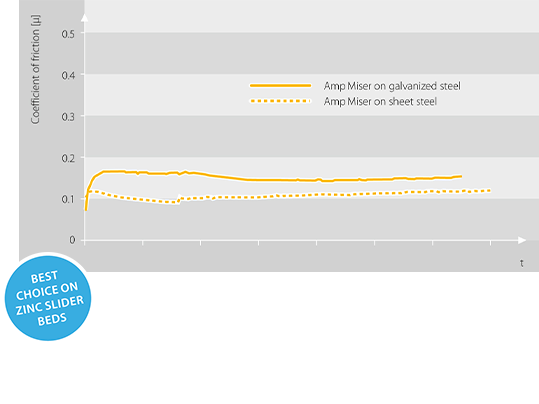

What problems arise on galvanized slider beds?

There are zinc coatings on the market that exhibit the same behavior as normal steel. Others are soft and produce zinc dust when abrasion occurs. This leads to black deposits on the bottom of the belt and a steep rise in coefficients of friction in standard belts.

Can Amp Miser belts be used on any type of conveyor?

Yes, but they’re not appropriate on every conveyor.

The following parameters are ideal for Amp Miser belts:

Amp Miser doesn’t require you to adapt the conveyor. Just fit the belt and you can start saving immediately.

What are the best arguments in favor of fitting Amp Miser?

End users reap the biggest benefits from installing Amp Miser belts. They operate their conveyors for many years and directly and sustainably save energy and running costs.

The benefit to OEMs lies in lower system costs due to design changes. Amp Miser belts that require 50% less energy entail the following benefits:

Low coefficients of friction against slider beds are good. But what happens in the drive drum?

Drive power always depends on the effective pull that the motor has to transmit.

Fu = m x g x μ (mass x acceleration of gravity x coefficient of friction). We can’t influence mass and acceleration of gravity Reducing the coefficient of friction by 60% on a steel slider bed also decreases the effective pull Fu by 60%. When elongation at fitting is the same, the grip on the drive drum is sufficient to ensure the belt is driven without creep. No changes are required on the conveyor.

How do I measure energy savings?

A proper comparative measurement can only be made by looking at consumption with a traditional electricity meter (effective efficiency in the three phases). All Forbo Siegling measurement results are based on this method.

What does ECOFIBER stand for in Amp Miser belt types?

100% of the tension member fabric is made from recycled PET bottles. Valuable raw materials are saved during production and waste is avoided without compromising quality or service life. At the same time, energy consumption and therefore CO2 emissions are significantly lower during production

One of Forbo’s key corporate objectives is to maximize environmental friendliness and to enhance product value at the same time. On this basis, we successfully conduct research and development by closely liaising with OEMs and end users. The energy-saving conveyor belts are another prime example of our approach.

TÜV Rheinland confirms that Amp Miser conveyor belts can realise significant energy and CO2 savings compared to conventional standard conveyor belts. For its savings potential of up to 50% of the energy required for power transmission, Amp Miser belts received the Best of Industry Award for Best Sustainability Project in 2023.

An additional sustainability benefit is derived from the selection of Amp Miser belts with tension member fabric made from 100% recycled PET bottles (Transilon ECOFIBER). Valuable raw materials are saved during production without compromising on quality and service life. At the same time, energy consumption and therefore CO2 emissions during production are significantly lower.

Amp Miser benefits

.webp)

Tests confirm that our Amp Miser conveyor belts have 50% less friction than comparable energy-saving belts. The comparable belts have the same high friction as our to standard belts without Amp Miser technology.

This results in up to 50% energy savings for baggage handling and intralogistics conveyor systems as well as reduced CO₂ emissions to support sustainability goals.

Read more about the exact measurement in the white paper

%20(1).webp)

Use our Amp Miser calculator to find out your potential savings compared to a standard belt.

Maximum savings can be expected with long conveyors, high loads, high, constant speeds and in horizontal transport. However, the lower coefficient of friction of Amp Miser belts also reduces energy consumption under other conditions.

TÜV Rheinland has certified the Amp Miser calculator. Use the user-friendly online calculator now.

To the Amp Miser calculator

Forbo Movement Systems is equipping Schiphol Airport with conveyor belts. Together with the supplier of the baggage handling systems, we are working on reducing the energy consumption of the baggage handling system by using energy-efficient belts. The Winning Solution describes the project of introducing Amp Miser and measuring the savings potential.

To the Winning Solution

In the white paper "Saving energy operating baggage handling systems", we examine the results of measurements in the laboratory and on active airport systems. They prove the energy-saving potential, also compared to comparable energy-saving belts in the market.

Amortization calculations show that possible additional costs are more than compensated for. Secondary effects such as longer belt service life and longer conveying distances with an identical drive can further reduce the overall costs of the system.

To the whitepaper

Our Amp Miser experts will be happy to answer any questions you may have about energy-saving belts.

get in touch now

.webp)

Due to a significantly reduced coefficient of friction, Amp Miser belts make an impact where energy losses in a conveyor are usually the greatest: in the friction between the bottom of the belt and slider bed. By adding patented Texglide to the underside fabric, a smooth layer is created that permanently acts like a dry lubricant and therefore minimizes energy consumption.

Amp Miser conveyor belts excel in areas where items are constantly conveyed and where many belts are in use, for example at airports and in logistics or distribution centers. Total energy savings of up to 50% have been measured In these types of applications.

Except where unpackaged food is concerned, the Amp Miser series is ideal for virtually any unit goods applications.

Further advantages are the resistance to chemical influences like kerosene vapors and the reduction of CO₂ emissions due to lower energy consumption.

| The properties | The advantages |

| ideal coefficient of friction for steel and zinc slider beds | energy efficient, eco-friendly, lower operating costs |

| lower coefficient of friction on the underside | less power required, longer conveyors possible with one drive |

| underside protected | cleanliness, long service life |

Our energy-saving Amp Miser belts have an excellent track record under the tough conditions in logistics centers and on baggage conveyors*. The Amp Miser belts with enhanced tension members and Texglide technology produce lower coefficients of friction between the underside of the belt and slider bed – even when slider beds are galvanized. No other changes to the conveyor are required.

*For more than 5 years Amp Miser conveyor belts have had a good track record in the following companies:

Compared with standard types, in typical applications with long conveyors and heavy loads, up to 50% energy savings are possible, now.

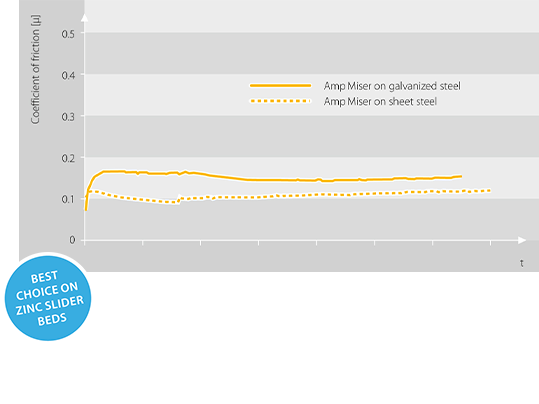

The second generation of Amp Miser types are also perfect on otherwise tricky galvanized slider beds. Compared with the previous belts, the coefficient of friction of this generation has been halved to

μ < 0.17. And it’s just μ < 0.13 on nongalvanized steel.

The quality, design and condition of all other mechanical and electrical components also play a major role in energy consumption as a whole. Small drives for example are usually not very efficient because a lot of the energy is required to drive the conveyor’s moveable parts alone.

Even with a low coefficient of friction, by using Amp Miser conveyor belts you can save up to 50% of the conveyor’s energy costs.

Significant savings can be made where:

The savings potential of Amp Miser, the absolute reduction in carbon emissions, as well as the online calculator’s accuracy, were independently confirmed by TÜV Rheinland.

Article number | Total thickness approx. [mm] | Weight approx. [kg/m2] | Effective pull at 1% elongation (k1% relaxed) [N/mm width]1 | dmin approx. [mm]2 | Permissible operating temperature [°C] | Horizontal conveying | Inclined conveying | Accumulation conveying | Flame retardant SE according to EN340 | Flame retardant FR according to ASTM D-378 | Energy savings certified by TÜV Rheinland | |

| E 10/2 TX0/V5H MT-AMP black | 906807 | 1.9 | 2.1 | 9.0 | 40 | –10/+50 | ● | ● | ||||

| E 10/2 TX0/V15 LG-AMP black | 906808 | 2.7 | 2.9 | 9.0 | 40 | –10/+50 | ● | ● | ||||

| E 10/2 TX0/V5H MT-SE-AMP black | 906809 | 2.2 | 2.5 | 9.0 | 40 | –10/+50 | ● | ● | ● | |||

| E 10/2 TX0/V15 LG-SE-AMP black | 906810 | 2.7 | 2.9 | 9.0 | 40 | –10/+50 | ● | ● | ● | |||

| E 12/3 TX0/TX0 FR-AMP gray | 907206 | 3.8 | 4.6 | 9.0 | 60 | –10/+50 | ● | ● | ● | |||

| E 12/2 TX0/V2 MT-M-FR-AMP black | 907224 | 3.0 | 3.6 | 6.0 | 60 | –10/+70 | ● | ● | ||||

| E 12/2 TX0/V1 | 907230 | 2.95 | 3.3 | 6.0 | 60 | –10/+70 | ● | ● | ||||

| E 12/2 TX0/V10 LG-M-FR-AMP black | 907229 | 3.9 | 4.5 | 6.0 | 60 | –10/+70 | ● | ● | ||||

| RE 10/2 TX0/V5H | 901015 | 2.2 | 2.6 | 8.5 | 36 | –10/+50 | ● | ● | ● | |||

| RE 10/2 TX0/V15 LG-SE-AMP black | 901016 | 2.7 | 2.9 | 8.5 | 36 | –10/+50 | ● | ● | ● |

Z-splice

Fulfils top demands on equal thickness. Very flexible splice. Standard splice for double-layer belt types.

Mechanical fasteners

For quick fitting and removal of the belt without dismantling parts of the conveyor.

AMP = AmpMiser

E = Polyester

FR = Flame retardant, ASTM D-378

LG = Longitudinal groove

MT = Matte

RE = Recycled polyester

SE = Flame retardant, EN340

TX = Texglide

V = Polyvinyl chloride

V…H = Polyvinyl chloride hard

1Established in line with ISO 21181:2005

2 Minimum drum diameter was determined at room temperature and does not apply to conveyor belts with mechanical fasteners. Lower temperatures require larger drum diameters.

What does Amp Miser mean?

Amp Miser is an abbreviation of “Ampere Miser”. The name emphasizes that installing an Amp Miser belt saves energy and improves your eco footprint as a whole. Our Amp Miser products are patented in Europe and the US. Patents have been submitted in many other countries too.

What does Texglide (TXGD) mean?

Texglide (TXGD) is a compound embedded in the underside of the fabric. Texglide isn’t just an add-on, or a coating, but a permanent feature of the bottom of the fabric throughout the belt‘s life cycle. Texglide guarantees low friction between the belt and the slider bed.

What material is recommended for slider beds?

Amp Miser belts can be used on slider beds of all types (such as wood, steel or galvanized steel). In the case of galvanized steel, the Amp Miser belts cut the coefficient of friction to under 0.17, as regards steel to 0.13 and to less than 0.06 in plywood.

What problems arise on galvanized slider beds?

There are zinc coatings on the market that exhibit the same behavior as normal steel. Others are soft and produce zinc dust when abrasion occurs. This leads to black deposits on the bottom of the belt and a steep rise in coefficients of friction in standard belts.

Can Amp Miser belts be used on any type of conveyor?

Yes, but they’re not appropriate on every conveyor.

The following parameters are ideal for Amp Miser belts:

Amp Miser doesn’t require you to adapt the conveyor. Just fit the belt and you can start saving immediately.

What are the best arguments in favor of fitting Amp Miser?

End users reap the biggest benefits from installing Amp Miser belts. They operate their conveyors for many years and directly and sustainably save energy and running costs.

The benefit to OEMs lies in lower system costs due to design changes. Amp Miser belts that require 50% less energy entail the following benefits:

Low coefficients of friction against slider beds are good. But what happens in the drive drum?

Drive power always depends on the effective pull that the motor has to transmit.

Fu = m x g x μ (mass x acceleration of gravity x coefficient of friction). We can’t influence mass and acceleration of gravity Reducing the coefficient of friction by 60% on a steel slider bed also decreases the effective pull Fu by 60%. When elongation at fitting is the same, the grip on the drive drum is sufficient to ensure the belt is driven without creep. No changes are required on the conveyor.

How do I measure energy savings?

A proper comparative measurement can only be made by looking at consumption with a traditional electricity meter (effective efficiency in the three phases). All Forbo Siegling measurement results are based on this method.

What does ECOFIBER stand for in Amp Miser belt types?

100% of the tension member fabric is made from recycled PET bottles. Valuable raw materials are saved during production and waste is avoided without compromising quality or service life. At the same time, energy consumption and therefore CO2 emissions are significantly lower during production