Real problem solvers

We developed our plastic modular belts to handle the food industry’s special challenges. We also have the series geared to your conveyor and application here.

We’re aware of the challenges posed by the agricultural sector, or dough, meat, poultry, and fish processing. And we get together with you to find solutions.

“Forbo’s Siegling Prolink modular belts are the perfect choice for the food industry’s stringent demands on reliability, performance and hygiene.”

Christian Reinhard, Segment Manager Food and Tobacco EMEA

Frequent belt replacements and unscheduled downtime due to wear can be expensive and disruptive. The belts need to be very tough to handle the difficult conditions in food processing. They also need to withstand chemicals, temperatures and mechanical load.

Arrange an appointment now

Superior reliability: Premium product quality ensures minimal downtime and maximum operational efficiency.

Maximum reliability: Minimal risk of cracks and breakage due to impact-resistant design and materials.

Optimized maintenance: Fast module replacement and easy repairs decrease disruptions.

Dependable operation: Wide hinges and rounded designs cut the risk of products getting caught in the belt.

Easy handling: With a huge choice of module designs, ideal for conveying products in all shapes and sizes.

Efficient on inclined conveyors: Reliable conveying whatever the gradient

Minimal downtime: The belts’ durability, fast service and modules that are easy to replace and repair keep downtime to a minimum.

Low maintenance costs: First-class engineering mean conveyors require little maintenance. ProSnap also provides quick and easy access to the belts for cleaning, repairs, and module replacement.

Lower procurement costs: Belts with longer service lives than rival products maximize cost efficiency.

Energy saving: Low-friction belts reduce energy consumption and save costs.

Siegling Prolink is approved as food safe to the HACCP, FDA and NSF standards. All Siegling Prolink modular belts made of POM are certified by the IFRC Asia (member of the World Halal Council) for compliance with Halal regulations. Go to the declarations of conformity

The belts were developed for fast and thorough cleaning. As a result, they maintain the quality of the food and extend its shelf life. To prevent contamination, the belt is resistant to bacterial growth. Made of food-grade materials, the material can withstand oil, grease and detergents. For greater product safety, Prolink can also detect foreign bodies better.

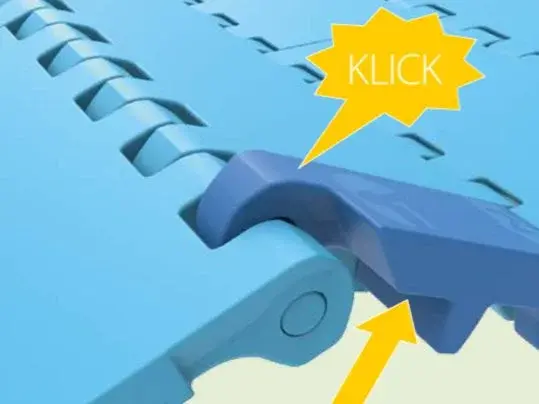

Plastic modular belts often need to be taken off the conveyor for cleaning (COP = cleaning out of place). In this case, operatives want to be able to open and close the modular belt rapidly and with ease. Which is why we developed the ProSnap release system. It’s available for Siegling Prolink series 4.1, 6.1, 10 and 13. The quick-release system is a real time saver. The belts stand apart for their flat surface (FLT) and exceptional strength. They’re made from POM and POM-MD (metal detectable).

The series 6.1 and 10’s tool-free opening capability, aided by a stainless steel hinge pin, is a real highlight. This hinge pin is easy to remove, even after a long time. As a result, maintaining and cleaning the modular belts is simpler.

Our service team looks after your plastic modular belts and production line as a whole. Forbo Movement Systems delivers a flexible range of services, from quick on-site deployment to various additional options to end-to-end servicing. Our employees have extensive belt expertise and service skills, superb tools, and equipment. What’s more, they only use approved processes and materials. Perfect results and long service lives are the result. Find out more about our services

Proven expertise: Underpinned by innovative technology and continual improvement, Forbo Siegling Prolink modular belts have a long-standing track record in the food industry.

End-to-end solutions: Comprehensive belt solutions for all food processing requirements.

First-class quality: Maximize your returns with first-class products from a market-leading supplier.

Achieve sustainability goals: With durable, recyclable belts that consume little energy. Decrease waste and help ensure sustainable conveyor designs. You also save space thanks to compact spiral conveyors because Siegling Prolink also operates reliably in tight curve radii.

Contact us if you’d like to know more