The customer

Vimek is an OEM located in the north of Italy which has 20 years of experience in manufacturing bakery lines including spirals, ovens, mixers, conveyors, etc. for the Italian, European and USA market.

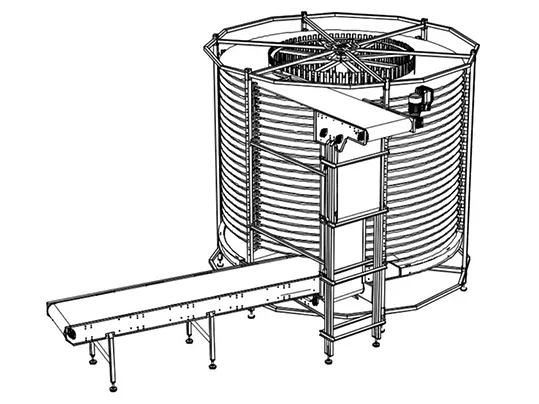

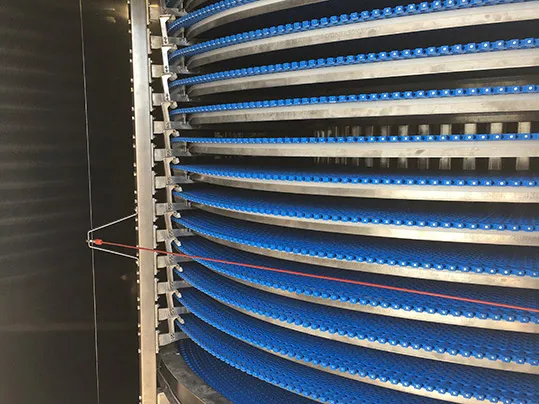

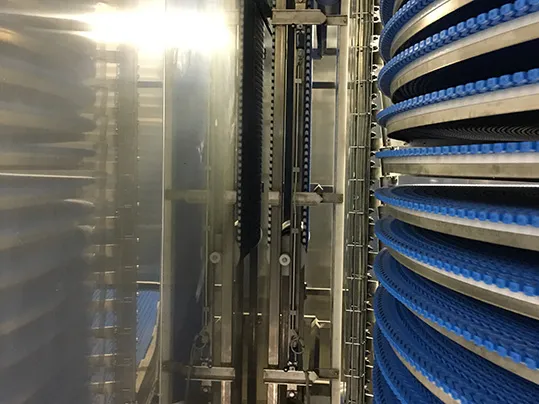

Vimek has an international patent for the design of spirals with external pulling (no drum). Those spirals are used for leavening, cooling and deep-freezing with every type of product. Vimek patented belt is a combination between steel pins, steel net and plastic modules.