Hanover, September 10, 2019 – Forbo Movement Systems is upgrading its series 14 Prolink belts by adding a new variant with a ½ inch (12.7 mm) pitch: series 14-25 FRT1 made of polypropylene with a friction top (PP).

The new series 14-25 FRT1 Prolink modular belt variant was custom-developed for applications requiring exceptionally good and secure grip. At the same time, these belts need to be able to operate over nose bars with very small return diameters (>= 19mm) without any limitations or vibrations when they pass over pulleys or belt transfer gaps. These sorts of challenging applications occur, for example, during inclined conveying of bread and rolls in bakeries and bread slicer infeed sections. Low-vibration transfer is also required in the packaging industry and associated areas, as well as in numerous other applications where a tough belt with particularly good grip (high friction coefficient) is required.

Series 14 requires just one hinge pin without a head per row, regardless of the belt width. Nevertheless, the pin is secured on both sides. This design makes assembly and disassembly very easy and fast.

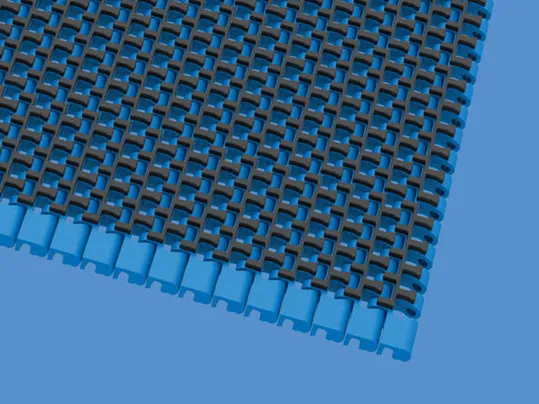

With an open area of 25% to allow superb airflow and drainage, this variant is easier to clean than the closed S14-0 FLT one. However, the S14-25 FRT1 and S14-0 FLT modules can be combined to achieve greater strength on the belt edges. All FRT patterns comply with FDA and EU directives. White/beige and blue/black belt and friction top color combinations are possible.

New Version of Prolink Series 14 with a Small Pitch and now also with a Friction Top for Vibration-Free Product Transfer

Forbo Movement Systems (previous called Siegling) employs more than 2,500 people globally in ten production sites and 25 international companies. Forbo conveyor and power transmission belts are used in nearly all industries, but also in the retail and services sectors. Key competencies are the food and packaging industries, logistics and airports, as well as paper, print and raw materials industries. The company was founded in 1919 in Hanover. Since 1994 the company has belonged to the Swiss company Forbo International. The products have been marketed since 2007 under the “Forbo Movement Systems” master brand.