January 2024

Hanover, January 2024 - The new Transilon belts E 12/3 U0/U15 GSTR green-T FDA and E 12/3 U0/U10 MT green-T FDA offer high process reliability and a long service life thanks to their robust three-ply design. They are also characterized by excellent grip, even with greasy or oily goods, as well as a matt surface to reduce light reflections and ensure cleanliness in production thanks to invisible abrasion and reduced susceptibility to dirt. These specially developed belts are used particularly in car body press lines, where they are used as unloading or inspection belts.

The robust three-ply construction of these belts reduces the risk of damage caused by hard or sharp-edged conveyed goods and at the same time offers the flexibility required for small deflections in compact systems. This is made possible by the polyurethane middle layer, which not only provides stability but also meets the requirements of modern, space-saving production systems.

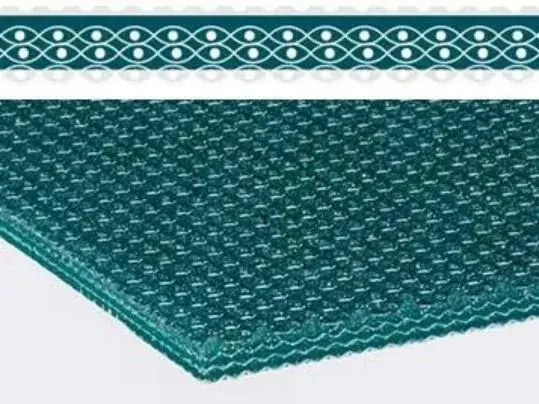

A special feature of these belts is the innovative “green-transparent” coloring. The transparent top layer allows a green polyurethane coating to shine through, which has the advantage that belt abrasion is barely visible on abrasive materials and unwanted soiling is less noticeable. This color concept sets new standards for belts used in highly abrasive environments.

The surface structures of the two belt types have been specifically tailored to different requirements. Type E 12/3 U0/U15 GSTR (art. no. 909238) has a coarse texture (GSTR) that enables smooth release of greasy or oily sheet steel and at the same time ensures optimum grip of the transported goods in inclined conveying. In contrast, type E 12/3 U0/U10 MT (art. no. 909240) has a matt surface that minimizes light reflection. This property is particularly advantageous in systems with optical sensors, for automated goods handling by robots or in systems with motion sensors. In addition to the automotive industry, the belts are also used in the building materials industry, metalworking, recycling and the wood industry.

With these new developments, Movement Systems is once again setting new standards in the transportation of heavy, hard and sharp-edged goods with solutions that combine efficiency and safety.

More information and data sheets