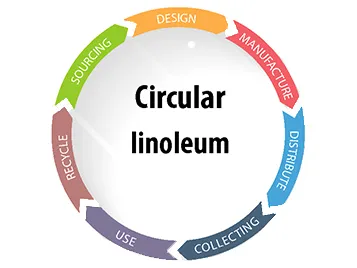

Circular by Nature

The essence of a circular economy is to preserve natural resources by retaining the quality and value of products and their parts.

For a circular economy the best thing is to prevent waste that is created in the first place. Choosing a floor that lasts more then 20 years is preferred to replacing a floor every few years.

If that is not possible it helps to choose a floor that is easy to remove. This gives an opportunity to reuse it somewhere else or makes it easier to recycle the floor.

Sustainable improvements do not stop at carbon neutrality. We are contributing to a circular world by walking the path to close the material loop for Marmoleum in every aspect of its lifecycle. Find out how we close the material loop for Marmoleum below.

The restoring capacity of natural resources is the bases for the circular economy. In essence linoleum is a bio-cycle product, this means that the natural raw materials basically could be composted and returned to earth as nutrients to the new grown rapid natural raw materials.

This is the only way to capture CO2 in a product avoiding off-setting necessity. The use of recycled, up-cycled (i.e. cocoa shells and tall oil) and re-used materials is a circular economy principle that has applied in Marmoleum for ages already.

By designing differently Marmoleum is made circular in several product solutions like the de-installable Marmoleum Click Cinch LOC, or replaceable and floating installations solutions for Marmoleum Modular.

The development of a true circular floor is a high priority project in our innovation team.

In our linoleum factories, the vast majority of linoleum waste is being re-used back into Marmoleum products. Other valuable streams, like jute or furniture linoleum backing paper residuals are offered to parties that upcycle them into highly valuable or socially responsible products.

A zero waste to landfill/incineration mission is pursued, a third party waste-management consultant is hired to reduce and upcycle all remaining waste streams.

With the cross-docking logistics and reuse of materials like pallets, circular principles are applied to the linoleum supply chain. Packaging of Marmoleum is made from renewable paper and is often re-purposed as masking protection paper or template during installation.

During installation, no waste needs to be made, while Forbo offers the 'Back to the Floor' service in countries close to our factories.

Installation residues are collected and added to the recycling system on our sites, contributing to the 43% recycled content in Marmoleum. Also note that Modular flooring reduces installation waste by approx. 7%, compared to sheet flooring.

In the use phase, the most important circular principle is a long product life. The key strengths that Marmoleum plays to is it's durability and timeless design. To further extend the lifetime, Marmoleum can be renovated and even restored to new with UV Careshield.

End of life, Marmoleum is in essence compostable, though that's a non-preferred low value solution.

Renoleum projects have been initiated since the beginning of 2018 and several end-of-life remanufacturing concepts were developed with partners, out of post-consumer linoleum floors.