Surface Regularity

Floored It Blog Series

The appearance, performance and durability of an installed floor covering will be determined to a large extent by the quality of the prepared subfloor and the conditions in which it is laid. Here, Craig Thornhill, Technical Services Manager at Forbo Flooring Systems, discusses the importance of surface regularity in ensuring a flawless finish.

Last year, the resilient flooring British Standard 8203:2017 added to the summary of the section on surface regularity as it was seen by the standard compilers to be a common marketplace issue that needed clarification. Section 6.2.3 in the standard has a useful commentary:

‘Surface irregularities can affect the overall visual appearance and wear life of the finished floor, resulting in premature wear, localized soiling problems, loss of bond with the installation of tile products, particularly large format tiles and geometric designs, and potential difficulties with the installation of sheet floor coverings where site-formed cove skirting details are used.’

*Published by BSI Standards Limited 2017

Due to budget constraints, particularly in new build construction, all too often we are seeing subfloors being insufficiently or poorly prepared. Flaws in surface regularity will consequently lead to problems both with the installation of the floor covering, as well as affecting its overall appearance and use. For example, an uneven, wavy, surface will create problems for wheeled traffic and have high spots where localized wear of the floor covering will occur.

For the installer, surface irregularities can result in loss of bond when installing tile products - both resilient and textile. This is particularly relevant in large installations and when dealing with geometric flooring designs, such as a herringbone pattern, where keeping tiles or planks in bond is essential if the desired aesthetic of the design is to be achieved. The problem is heightened when the unevenness is sporadic throughout the installation, which leads to tiles running out of bond in all directions.

When it comes to installing sheet floor coverings with site formed coved skirting, it is still necessary to check the surface regularity of the subfloor. However, with the flooring material being coved up the wall, the straightness of the wall and consistency of the angle between the floor and wall are also factors that need to be considered.

Sheet flooring, being a flat produced product, will quite happily bend two-dimensionally – so a flat floor and straight wall with a consistent angle makes for the perfect substrate on which to install. However, sheet products are not designed to bend three-dimensionally, so uneven subfloors and irregular walls can contribute to stressing the flooring, leading to non-adhered sections, creases in the floor covering, or hollows behind the floor covering and cove former.

Even minor unevenness in the subfloor can cause the extruded PVC cove former to move up and down when fixing (basically following the floor profile) which in turn will cause the sheet material to have to try to bend in three dimensions – resulting in adhesion problems and the likelihood of failure long term.

According to the British Standard 8203:2017, the guidance states that:

“The class of local surface regularity of a directly finished base or levelling screed, if used, should be selected in accordance with Annex C, Table C.1, according to the use of the floor. In making this selection, account should be taken of the type and thickness of the wearing screed or flooring to be applied and the standard of surface regularity required of the finished floor. The highest standard (SR1) should be used where a thin flooring is to be applied and where the minimum irregularity is required of the finished floor, e.g. for a television studio.

NOTE: Conversely, the lowest standard (SR3) can be selected where a thicker type of wearing surface is applied and where the regularity of the finished floor is not a significant factor.”

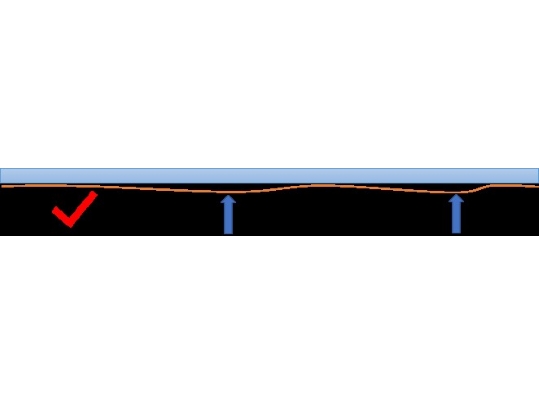

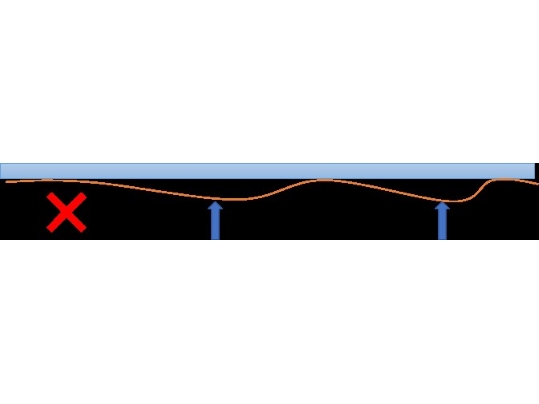

In accordance with Annex C (normative) of BS8204-1:2003 & A1:2009, the surface regularity of a screed for normal accuracy flooring is measured using a 2m long straightedge laid in contact with the floor surface ensuring that it is resting under its own weight. The deviations of the floor surface from the underside of the straightedge are measured between the points which are in contact with the floor surface. This can be carried out by means of a slip gauge or other suitable accurate measuring device.

With this type of measurement, the various interested parties involved should come to an agreement at the design stage regarding the sampling rate for testing and the procedures to adopt if conformity is not achieved. From a practical standpoint, it is wise to include the number of positions where the straight edge will be placed to more thoroughly check conformity.

Acceptable = variations no greater than 3mm per 2metre straight edge

Unacceptable = variations greater than 3mm per 2metre straight edge

Before starting any installation, it is critical that contractors ensure that the subfloor is ready for the floor covering to be installed. Surface regularity should be agreed as standard prior to a project starting and then monitored during a project fitment to ensure all parties achieve a mutually acceptable finished floor. After all, the finished floor is only as good as the base or subfloor on which it is laid.