Bringing environmental goals to life

Big sustainability goals only matter if they lead to real change. At Forbo Flooring Systems, we’re turning ambition into action, across materials, production, packaging, and more. This blog shows how our 2030 environmental targets are already making a difference on the ground, and what they mean for your projects. From cutting emissions to scaling up circular solutions, here’s a practical look behind the scenes.

At Forbo Flooring Systems, we believe sustainability is something you do, not just something you talk about. It’s built into every step we take: from the materials we choose to how our floors are installed, used, and eventually recycled.

To keep ourselves accountable, we regularly publish reports that openly track our environmental, social, and governance performance, including third-party verified Environmental Product Declarations for our products. It’s our way of sharing progress transparently, so you can make better-informed decisions about the materials you work with.

We’ve laid out our ambitions clearly in the 2024 Sustainability Report. But what do those goals look like in practice? And more importantly, how do they make a difference in your projects?

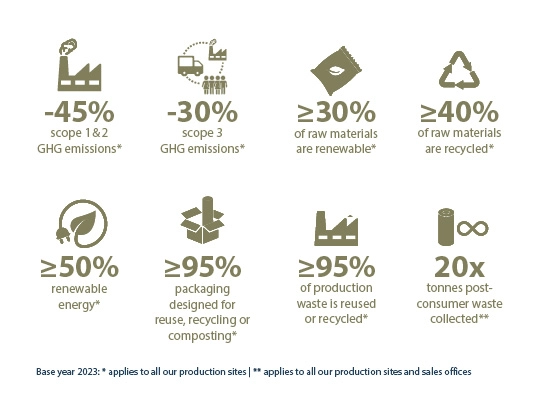

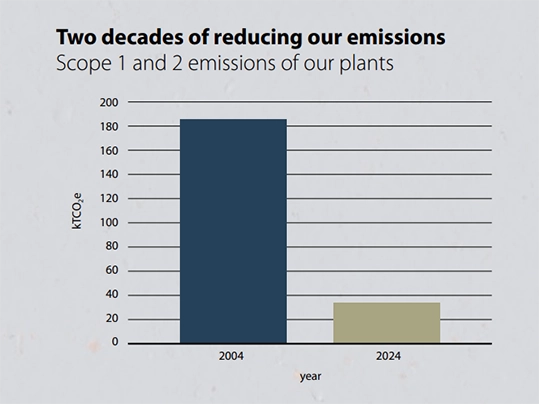

By 2030, we aim to reduce our Scope 1 and 2 emissions by 45%, and Scope 3 emissions by 30% compared to 2023. It’s a technical goal, sure—but the actions behind it are surprisingly down to earth.

We’re already powering all our production sites with renewable electricity, and we’re working with local suppliers to keep transport emissions low. In fact, since 2004, we’ve cut our Scope 1 and 2 emissions by 81%. And we're not stopping there. Ongoing investments in renewable energy, efficiency upgrades, and smarter logistics are keeping us on track.

Scope 1 – Direct emissions that are owned or controlled by the company.

Scope 2 – Indirect emissions from purchased energy consumed by the company.

Scope 3 – Other indirect emissions that occur in the value chain, both upstream and downstream of the company.

True circularity goes beyond recycling. It starts at the design table. We’re creating flooring that is made to be reused and disassembled.

That’s why we’ve expanded our adhesive-free Fast Flooring collections. They’re quick to install, easy to remove, and ready for a second life. And through our Back to the Floor take-back program, we collected over 600 tonnes of post-consumer flooring waste in 2024 alone, including installation and end-of-life waste. It’s practical circularity that works on real building sites.

As part of our journey towards becoming a zero-waste company, we’re continuously refining our production processes to minimise waste. All our production sites run initiatives to prevent and valorise waste, reducing, reusing, and recycling wherever possible.

For the waste that can’t be avoided, we’ve set a clear target: more than 95% of it will be either reused or recycled, keeping valuable materials in the loop and out of landfill. In fact, in 2024, we already managed to recycle 80% of our production waste, either internally or through external partners, showing we’re well on our way.

Packaging is part of the picture too. By 2030, 95% of our packaging will be recyclable or reusable, making your projects cleaner and greener from start to finish. In 2024, we also collected over 100 tonnes of Eurocol adhesives packaging material.

We’re constantly rethinking what goes into our products, choosing materials that are better for people and the planet.

Today, around half of what we make comes from bio-based, recycled, or abundant raw materials. Marmoleum is a perfect example: made from renewable materials like linseed oil, jute, wood flour, and other natural ingredients, it’s climate-positive from cradle to gate without offsetting. That means it stores more carbon than it emits during production, until it leaves our factory gate.

For our customers, that translates to lower embodied carbon, healthier interiors, and a smarter environmental profile from day one.

Transparency is on of our core sustainability principles, that’s why we have listed all of our embodied carbon and recycled content figures all in one place. View the EPD & Embodied Carbon brochure here.

We’ve been extending the useful lifespan of our flooring through donations to The Salvation Army Trading Company (SATCoL). As part of this partnership, we have supplied The Salvation Army with donations of surplus Tessera carpet tiles, supporting its Take Back and furniture shops.

The initiative not only provides a second life to carpet tiles that may otherwise be sent to landfill, despite having many more years of use in them, it also gives access to high-quality, affordable flooring for those that need it most.

So far, SATCoL has raised £25,000 from our carpet tiles.

Find out more about the Forbo x Salvation Army Partnership

Our save a sample scheme encourages customers to return samples to us once they have served their purpose. This allows the samples to be re-used or recycled rather than thrown in the bin, and ultimately reduces the amount of material going to landfill.

Since the introduction of the ‘Save a Sample’ service in 2010 the scheme’s popularity has been growing steadily each year. The quality of the samples returned is so high that the vast majority of samples (approx. 85%) can be reused so reducing the need to order virgin sample material.

Whether you're aiming for a sustainability certification like LEED, BREEAM or WELL, or just looking to reduce your project's environmental impact, we’re here to support you with solutions that make a real difference, without compromising on performance or design.

Our floors are already being used in projects around the world to help lower embodied carbon, improve indoor air quality, and meet sustainability goals with confidence. And because we believe in measurable progress, we back everything up with transparent ESG reporting, third-party verified EPDs, and a clear roadmap you can rely on.

If you’re looking for a flooring partner that keeps things practical, honest, and forward-thinking—we’re ready when you are.