Designing with circularity in mind

A look at the different ways we can design more sustainable products and work towards circularity in the flooring industry.

Circular design is a considered and intentional approach to product design that seeks to eliminate product waste. It aims to create a closed loop whereby products are not thrown away at the end of their lives. Instead, they can be reused. For example, modular design is a common circular solution – it allows products to be disassembled and their parts reused in new products.

While the flooring industry still has a long way to go in embracing circularity, there are circular flooring systems that are ready to be implemented.

These solutions will help the construction industry to drastically reduce its waste and meet sustainability targets. Forbo Flooring is at the cutting edge of circular flooring – and it all starts with product development and design.

Each year, around 3 billion m2 of flooring is produced in Europe alone. Around 34% of that is carpets, 15% laminate and 10% vinyl.

Unfortunately, there are still various aspects preventing most of that flooring from being recycled or reused at the end of its life. The design of flooring products, including both materials and installation method, are often obstacles to a closed-loop system.

For example, floors are often made up of multiple materials which are hard or impossible to separate for recycling. They may also require adhesive for installation, which again makes it difficult to reuse or recycle the flooring materials.

Circularity is about eliminating waste, so it is tempting to focus on the end of a product’s life – how it can be disposed of or recycled. But circularity goes beyond recycling. It’s thinking about the end of a product’s life right from the start and designing products so that little to no waste is created.

When designing products, we need to think about what will happen to them when the customer is finished with them. They need to be designed so they can be removed, dismantled and used again. A successful way to do this is to create and install adhesive free flooring. The adhesive that is traditionally used to attach floors contaminates the flooring itself so it’s very hard to reuse or recycle it.

Our unique Fast Flooring products can be installed without adhesive, meaning they are easy to dismantle and can be used again in different places and applications. These are the kind of innovative solutions we need to achieve long-term sustainability in the flooring sector.

Another way to ensure flooring lasts longer is to make sure it's fit for purpose. And not just on a practical level. While it’s important that flooring has the correct physical qualities to withstand and support their environment, we can go beyond this and also focus on how flooring makes us feel.

Forbo’s design philosophy “The dynamics of a building” utilises the colours, textures and feel of different flooring to create appropriate, supportive environments for work, rest and more. Providing the right flooring means it will be used longer, reducing waste.

As well as designing modular flooring that can be reused, materials need to be recyclable too. Linoleum, for example, consists of natural materials that are easy to recycle into new flooring, while vinyl can be recycled up to 10 times without any loss in performance. In cases where recycling is not an option, it is good to know that, because of a high calorific value, it can be burned to generate energy.

All our floors use eco and human safe recipes that contribute to the health of the people using buildings. Products like phthalate-free vinyl, Allergy UK Approved Flotex and natural Marmoleum create good indoor environments. These floors can also be reused and recycled for years to come, without causing harm.

Circularity continues to play a big role in our sustainability goals for the future. We want to keep contributing to the circular economy by increasing the recyclability of the products that we sell and by making sure that all products contain as much recycled content as possible.

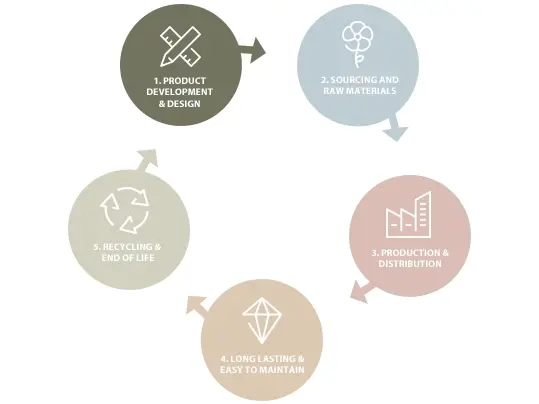

Product design is just one piece of the puzzle when it comes to designing circular solutions for the flooring industry. We also need to consider the raw materials used, production and distribution, maintenance and recycling. You can learn more about each of these areas in our blog series.

Next up, find out how we make sure the materials we use and how we source them allow us to give more back to nature than we take in our next blog in the series: Sourcing for Circularity